2 min read

Testing, For Real: Innovative Testing System Simulates Real-World HDD Risks of Coating Damage

David Futch, PE

8/4/23 12:38 PM

David Futch, PE

8/4/23 12:38 PM

As pervasive urban sprawl, expanded city layouts, and increased development lead to more congested rights of way for pipelines, installing pipelines underground using techniques such as horizontal directional drilling (HDD) will become more common. However, there is an increased risk of coating damage from HDD from abrasion, impact, gouging, denting, tearing, and bending. Therefore, there is a need for a high-quality protective overcoat that will prevent damage to the pipeline coating before it is even put into service. This protective overcoat requires comprehensive validation testing to be trusted by the industry.

However, the current subscale testing methods typically used to validate these types of coating may not adequately address or simulate the real-world stress or damage that the coating would encounter in HDD. To overcome the inadequacies of typical subscale testing, ADV Integrity designed an innovative testing system that combines subscale testing with full-scale testing to simulate the real-world stresses associated with HDD.

Drilling Down Into the Testing Design

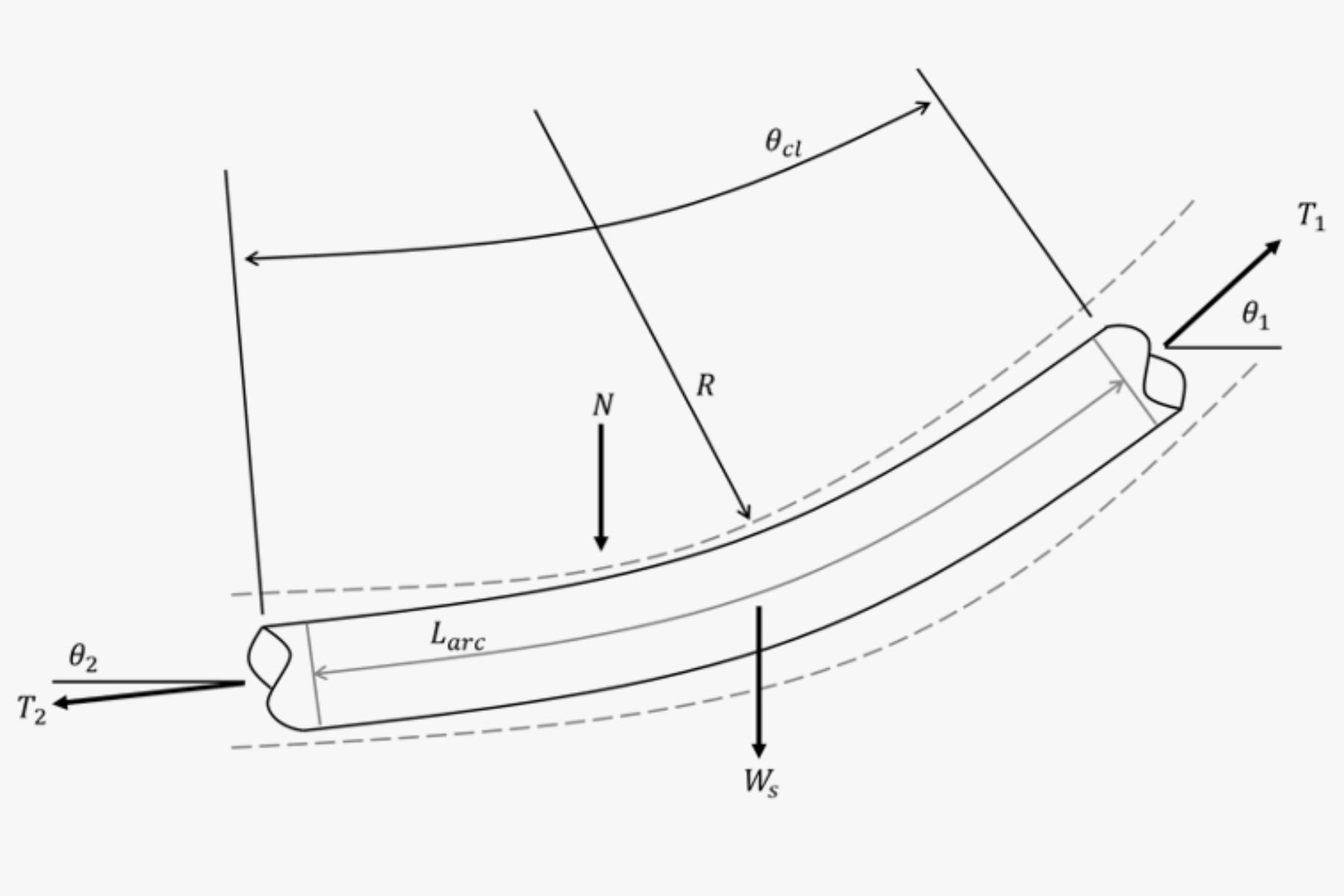

The load incurred during HDD is a function of axial force, the ballast or mud used during the pull, and the resultant friction between the pipe and any external formation. Loading during HDD can be substantial; however, the commonly used test for validating coating—known as the Taber Abrasion test—simulates loads that do not adequately represent the substantial stress pipeline coatings may encounter during HDD. First introduced in the 1930’s for accelerated wear testing, the Taber Abrasion test involves a mounted specimen that rotates on a vertical axis. This kind of subscale testing is acceptable as a reproducible quality check, but a different testing approach was needed for coating qualification testing.

Building a Full-Scale Alternative

A full-scale testing system was designed to supplement the Taber Abrasion and other subscale tests. The full-scale system would simulate the real-world obstruction and risks for HDD. To develop the system, ADV Integrity first calculated the normalized normal force for various conditions: pipe diameter, pipe wall thickness, mud density, and curved segment length. The results of those calculations were used for applied loads during the full-scale test, with the maximum load being 1,000 lbf. The testing design simulates the pipe being pulled through the drilled hole while controlling both the obstruction and the load applied by the obstruction.

The Set Up

The testing frame included three pneumatic cylinders affixed with different obstructions: a granite block to represent rock found in the natural formation; a round top to represent wear pulling the pipe through the hole; and, a carbide-tipped machining insert to simulate aggressive gouging. The pipe was pulled through the obstructions with a winch. There were 22 total test pulls completed for the project with different layer counts and applied load combinations.

Using a combination of subscale and full-scale testing, ADV Integrity could provide comprehensive third-party testing and qualification of an abrasion-resistant overcoat by simulating HDD more realistically. With the results, users of the overcoat can be more confident in its ability to protect assets during pipeline construction projects.

Originally published March 10, 2023