ECA Level 1

A basic assessment using conservative guidelines and assumptions. Provides a quick estimation of structural integrity and susceptibility to flaws in engineering components.

Engineering Critical Assessment (ECA) is a methodology used to evaluate engineering components' structural integrity and safety, particularly in high-stress environments or critical applications. ECA is often applied to assess the integrity of structures, such as pipelines, pressure vessels, and offshore platforms, which are subject to high-pressure, high-temperature, or other extreme conditions. Here at ADV, we use ECA to determine the presence and significance of flaws or defects in components, such as cracks or weld defects, and to assess their potential for propagation and failure.

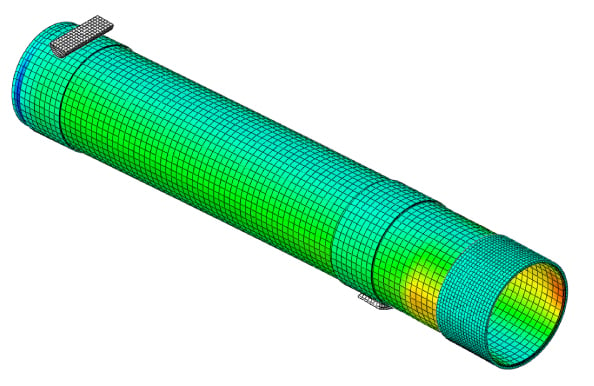

ECA involves a detailed analysis of components' design, material properties, loading conditions, and existing defects. The assessment combines analytical calculations and numerical modeling to predict the component's behavior and determine its safety margins. By performing ECA, our engineers can ensure that clients' technologies are designed, operated, and maintained to meet the required safety standards, thereby reducing the risk of failures that could have severe consequences for human safety and the environment.

A basic assessment using conservative guidelines and assumptions. Provides a quick estimation of structural integrity and susceptibility to flaws in engineering components.

Advanced calculations and FEA, refining models to assess structural integrity more accurately, providing higher confidence in critical component evaluation.

A more rigorous assessment to comprehensively evaluate critical components, ensuring utmost confidence in structural integrity and safety.

Our lab techs can scan components and assets using a Creaform scanner to digitize pipe threats into 3D renditions and models for further analyses.

Using various forms of analyses, ADV can help clients make sure they are complying with the latest regulations and industry standards.

Identifies underlying reasons for defects and issues. We use analyses to uncover core problems, enabling effective solutions and prevention strategies.