Static Pressure Testing

Hydrostatic proof, leak, and burst testing up to 60,000 psig liquid and 20,000 psig gas for pipes and equipment.

Using ADV Integrity’s Technology Readiness Levels (TRLs), based on API’s RP 17N (June 2017), Recommended Practice on Subsea Production System Reliability, Technical Risk, and Integrity Management, we work on the forefront of innovation and technology to take products from an idea all the way to the end consumer.

The concept of Technology Readiness Levels (TRLs), commonly used in the aerospace and defense industries, provides the pipeline industry with a proven means for evaluating and assessing technologies used to enhance integrity management efforts.

The adoption and implementation of the TRL approach will minimize operator risk and foster the deployment of advanced technologies, thus enhancing the safe operation of high-pressure pipelines. Three TRL-oriented case studies will be included evaluating the monitoring of pipelines using fiber optics, inspection using three-dimensional imaging, and reinforcement using optimized composite technologies.

One of the goals of TRLs is to provide the pipeline industry with a framework for determining where a particular technology is in terms of the overall TRL framework.

In other words, is the technology still at TRL 2: Demonstration by Testing or is the technology further along this process and actually at TRL 4: Prototype Validation? Knowing how to distinguish between the different TRLs is important for the following reasons.

It’s easy for technology developers to believe they are farther along in the TRL process than they actually are. This is not a technical issue; rather, it is an emotional issue and requires that the technology developer divorce themselves from the design and development process to conduct an objective assessment of where they are in the process.

Oftentimes, third party organizations with technology experts or potential technology users are ideally-suited to partner with innovators in going through this process.

Knowing where a technology resides in the TRL process permits stakeholders including technology innovators, users (i.e., operators), regulators, service companies, and investors to better understand where they are and where they need to be.

It does not benefit key stakeholders to believe a technology is further along in the TRL process than they really are. The TRL process provides a framework for knowing where to focus to ensure the technology development process advances appropriately, with the eventual goal of every technology to achieve TRL 7: System Operation.

The TRLs allow interested parties, namely technology innovators, developers, users, and investors, to have a framework against which to measure the technology development stage. This ensures that the technology development process advances at a reasonable pace, ensuring internal accountability among team members regarding performance expectations and associated risks of achieving the desired TRL levels.

Hydrostatic proof, leak, and burst testing up to 60,000 psig liquid and 20,000 psig gas for pipes and equipment.

Perform up to 10,000 cycles per day on various pipe diameters up to 3,000 psig with our pressure cycle systems.

3 or 4-point bending frame with a capacity of 3,000,000 ft-lbf, accommodating pipes up to 32" diameter and 30' length.

Our test chamber is 20’x8’x7’ and capable of testing to -50°F.

Shielded environmental chambers capable of temperatures from 350°F to -60°F for a range of sample sizes.

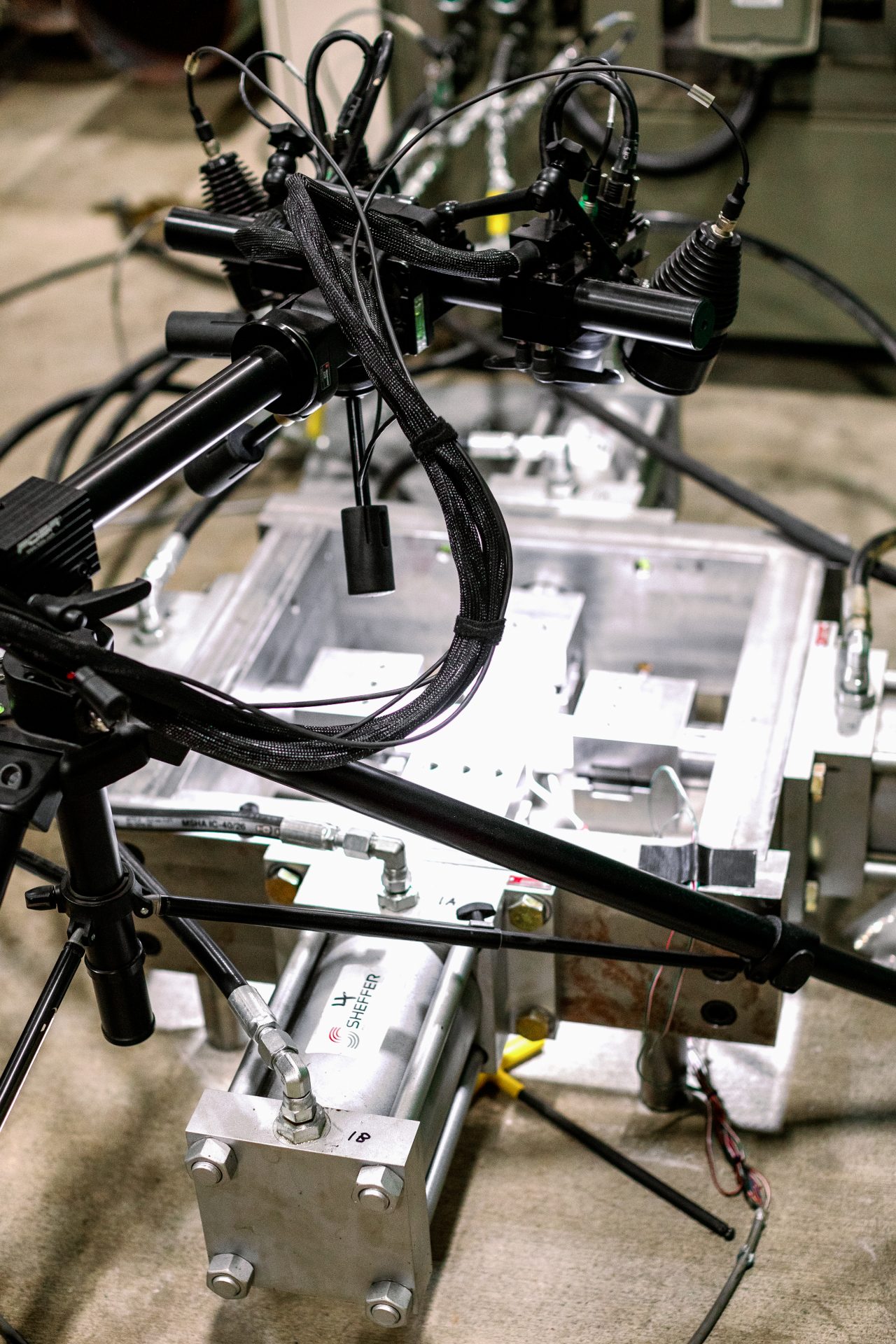

Premier data acquisition equipment, diverse instrumentation, including DIC system and Creaform 3D scanner for precise testing.

100-kip load frame for tension/compression, fatigue, and toughness tests on sub-scale samples with environmental chamber for varied temperatures.

Custom test fixtures designed and fabricated for external, thermal, or internal pressure loading scenarios.