2 min read

When In Doubt, Model It: How FEA Models Can Address Composite Pipeline Repairs’ Toughest Challenges

Ahmed Hassanin, MS

8/4/23 11:40 AM

Ahmed Hassanin, MS

8/4/23 11:40 AM

Traditional testing and inspection methods of composite repairs are great for telling you about the past or current state of the repair. However, a significant challenge for pipeline operators is understanding what will happen to composite repairs installed under different operating conditions.

There’s an FEA model for that (with proper verification and validation)

Bridging the gap between past and future, ADV Integrity’s finite element analysis (FEA) processes use advanced modeling technology to simulate real-world physical problems and predict pipeline behavior under operating conditions. When excavating and removing material from an in-service pipeline for full-scale testing is not feasible, too costly, or likely to cause excessive time delays, FEA can provide quick, reliable, and cost-effective solutions. The caveat is ensuring accurate inputs and providing proper analytical interpretation of outputs.

ADV Integrity’s FEA capabilities include not only analyzing pipeline behaviors in specific operating conditions but also predicting behaviors. This composite repair analysis provides vital information to operators about the response of the pipeline repair, their utilization, as well as their compliance with regulatory limits.

In the following analysis case study, ADV Integrity developed and implemented an FEA process to model and analyze the efficacy of composite repairs for an unrestrained plain dent anomaly.

Case Study: FEA Process for Analyzing Pipeline Dent Composite Repair

In a process developed by Ahmed Hassanin, ADV Integrity’s FEA Roadmap incorporates pre-analysis tasks, elastic analysis, elastic-plastic nonlinear analysis (level 3 assessment), and post-processing.

Pre-Analysis: The first step in the process is to collect the required data from the pipeline operator including: dent installation pressure, operating pressure history including any subsequent pressure tests, and the composite repair design. This information serves as the basis for the FEA model ensuring that the numerical analysis is an accurate reflection of the pipeline conditions during and after indentation.

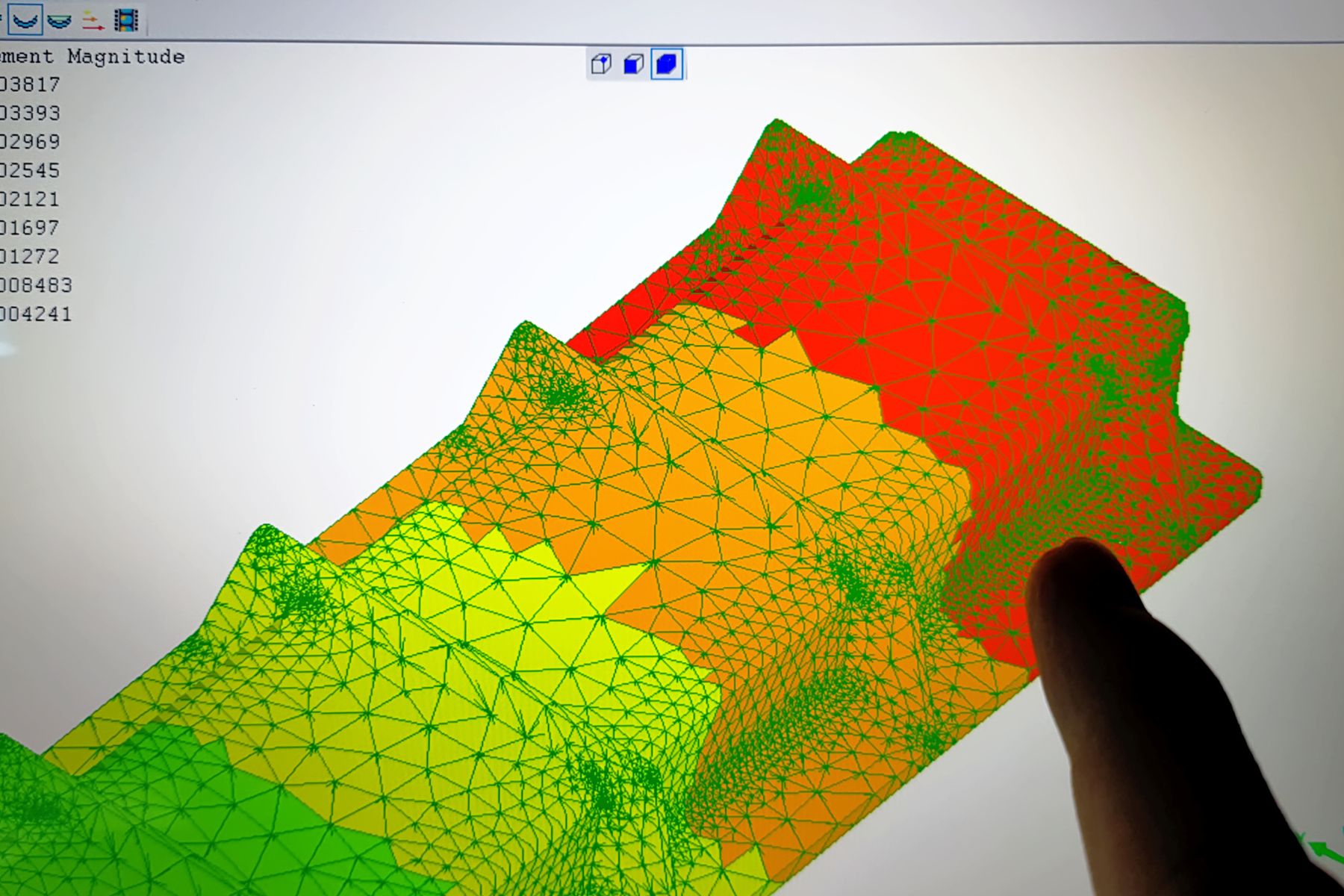

Elastic Analysis: In this first analysis step, a preliminary geometry of the dent anomaly is modeled based on radii data from an inline inspection (ILI) tool. An elastic numerical analysis is used to calculate the stress concentration factor (SCF) associated with an unrepaired dent based on internal pressure according to established industry procedures. Next, a secondary elastic model that incorporates the composite repair is generated. The composite repair model accounts for different aspects of the composite repair, including the composite layout (modeled as lamina), the filler material and epoxy (modeled as springs and tie constraints), and the conformance of the repair to the pipe geometry. The SCF from the repaired model can be calculated and compared to the SCF from the unreinforced elastic model. Using elastic models permits the analysis to be completed quickly and provides an excellent indication of the effectiveness of the composite repair.

Elastic-Plastic Nonlinear Analysis (Level 3 Assessment): In this next analysis step, which is dependent on whether the elastic model’s results are favorable, the dent geometry is developed by indenting the pipe rather than using ILI data. The purpose of this analysis is to explicitly account for residual strain from the dent formation and the impacts of material plasticity. The level 3 assessment is more comprehensive as it involves the analyst calibrating an indenter shape to match the data gathered from the field or the ILI tool. Like the elastic analysis, both unreinforced and reinforced models are analyzed to compare the SCF values.

Post-Process Data: Finally, the analysis is evaluated to determine two critical results: the influence of the composite on the strains in the dent, and the strains experienced in the composite. Using the acceptable limits established by ASME PCC-2, ADV Integrity can ensure the integrity of the composite repair and make judgments about the safety of the strains in the composite repair at operating and hydrotest pressures.

Know Your Analysis Options

When a situation calls for timely and cost-effective consultations on the safety of assets, FEA can provide an alternative to traditional testing, while still providing accurate and reliable results.

Originally published June 28, 2022