3 min read

Unlocking Precise Insights: How ADV Gets Impactful Data through 3D Laser Scanning

Ahmed Hassanin, MS

8/8/23 8:00 AM

Ahmed Hassanin, MS

8/8/23 8:00 AM

At ADV Integrity, we use a variety of technologies to assist us in enhancing the value of our technical services for our clients, and in developing cutting edge solutions for pipeline integrity management. 3D laser scanning is one such technology that we use to augment the defect/feature assessment and analysis processes in pipelines.

What is 3D laser scanning?

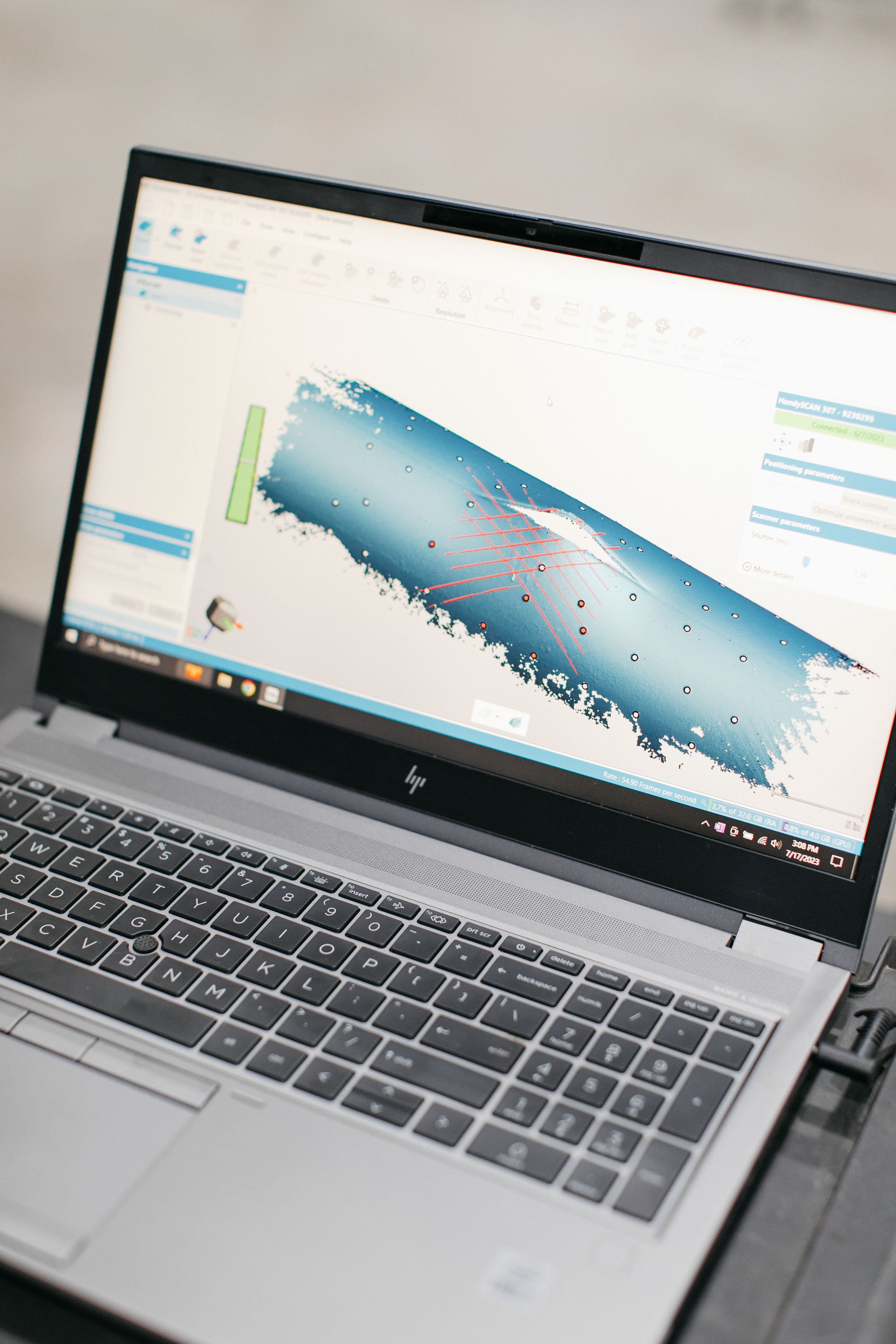

In the context of pipeline integrity, 3D laser scanning is typically engaged as a metrology tool for Non-Destructive Examination (NDE). The system utilizes a laser scanner and specialized software to capture the shapes and profiles of defects/deformations in pipelines so that they can be modeled or analyzed. 3D laser scanners come in many forms, but portable 3D scanners are the primary type used for pipeline inspections due to their portability and high accuracy.

The Hardware

Our trusted hardware of choice for this process is the Creaform HandyScan 307™, a powerful tool that enables precise scanning and inspection capabilities.

The Creaform HandyScan 307™ offers an impressive resolution of 0.0039 inches (0.1 mm), which is equivalent to the size of a grain of sand, enabling us to capture even the finest details. When it comes to accuracy, this system excels, with an accuracy of up to 0.0012 inches (0.04 mm), ensuring reliable and highly accurate measurements. The measurement rate of this scanner is also noteworthy, with a capability of 480,000 measurements per second, enabling efficient and rapid scanning. Moreover, the system can accommodate a wide range of part sizes, capable of scanning objects ranging from 0.3 feet to 13 feet (0.1 – 4 meters) in size.

The Software

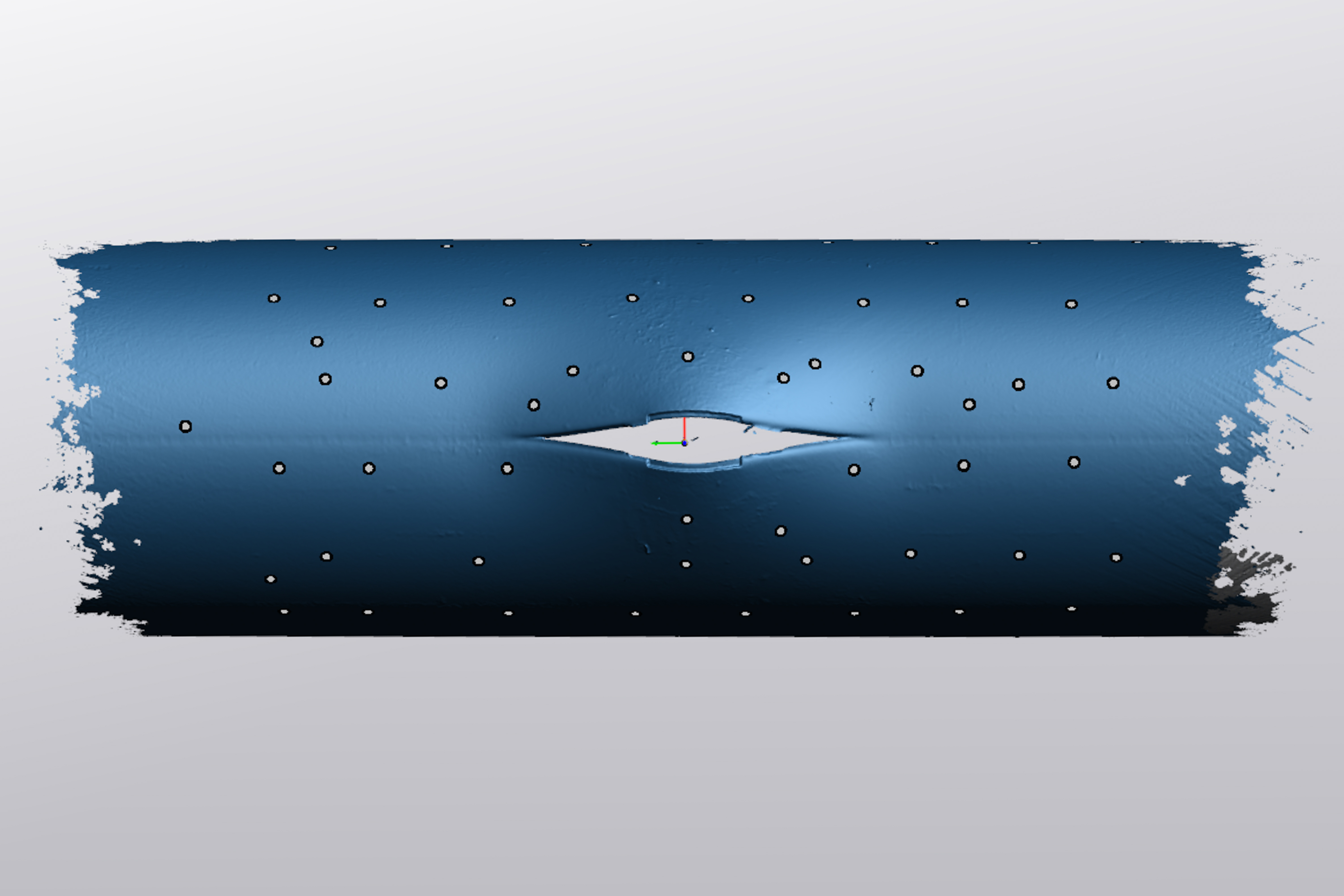

In addition to Creaform’s powerful hardware, we utilize two distinct software programs: Pipecheck and VX Elements. Pipecheck is a specialized solution designed specifically for scanning and inspecting pipes with typical defects (such as metal loss, dent, etc.). VX Elements, a versatile software package, allows us to scan and inspect non-pipe components (and non-standard pipe features) with equal efficiency and accuracy.

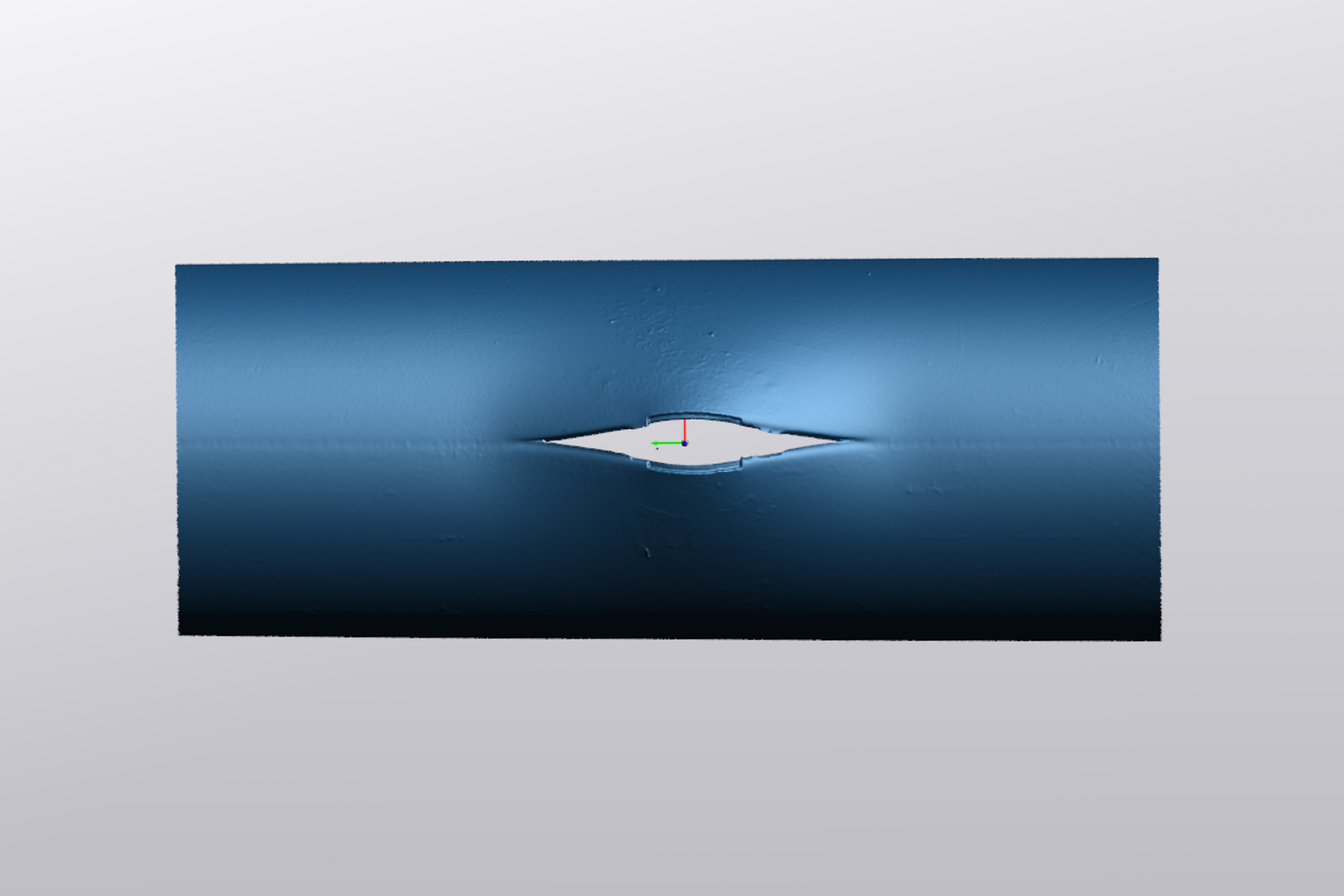

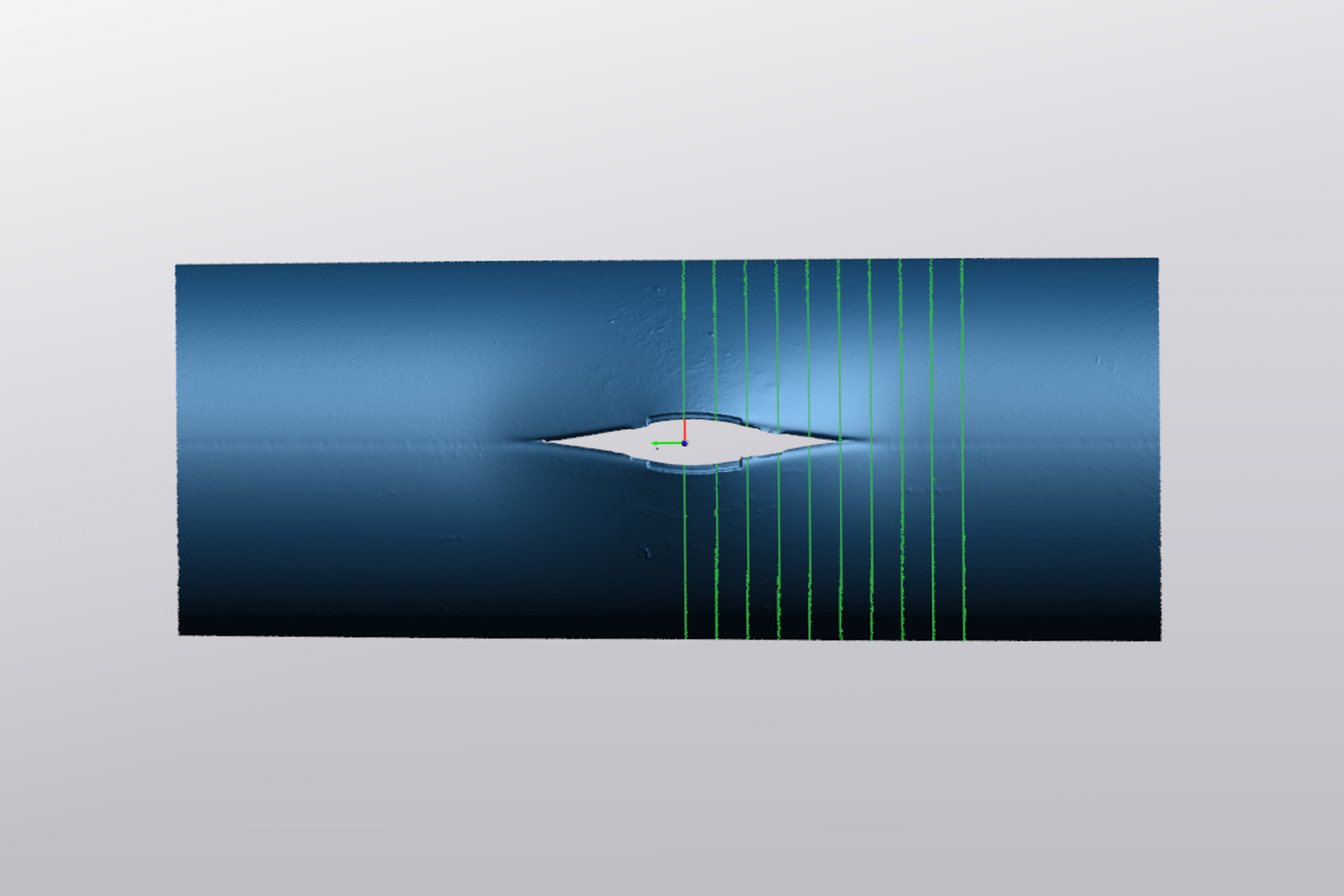

Pipecheck offers comprehensive analysis capabilities for corrosion, dent, wrinkle, and ILI (In-line Inspection) to laser scan correlation. With Pipecheck's corrosion analysis, users can accurately determine the depth and size of corrosion features, enabling them to assess severity and make informed decisions for integrity management. The software also provides users the ability to determine the failure pressure based on industry standards such as B31G, Modified B31G, and RSTRENG (Effective Area method). For dent analysis, Pipecheck presents users with the information to determine the depth and size of dents and calculate dent strain based on ASME B31.8 - Appendix R, enabling accurate dent assessment. Pipecheck also offers ILI-to-scan correlation capabilities, allowing for the superimposition of ILI data callouts onto scan callouts, enabling the identification of unity, defect growth, new features, and more.

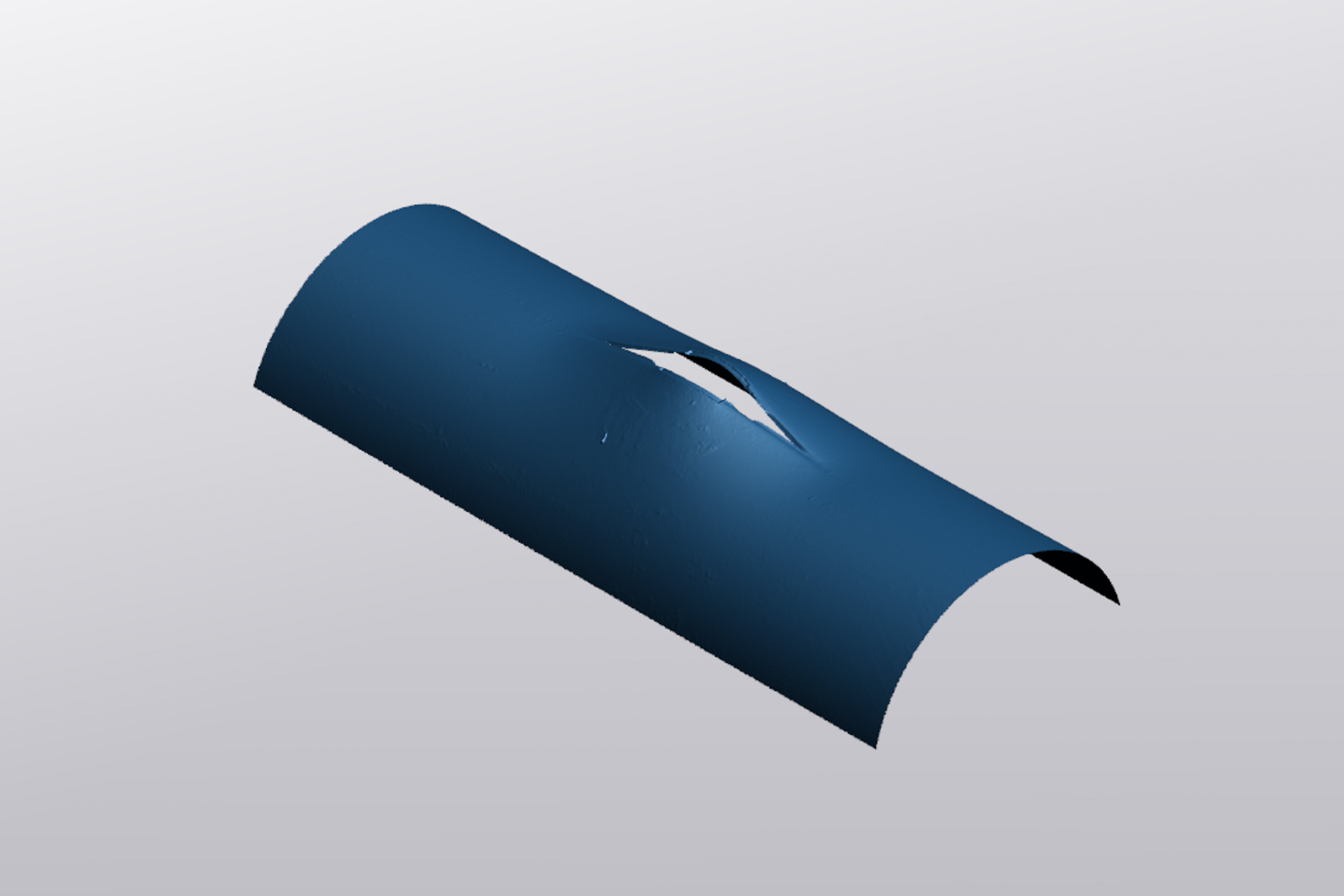

VX Elements has advanced capabilities including accurate analysis of ruptured surfaces, thickness variations across failed surfaces, and pipe bending. A powerful feature of the software is that it allows for the generation of CAD files that can be directly exported for finite element analysis (FEA) by “cleaning” the scans – this capability expedites the setting up of finite element models for Level 3 analysis of flaws/features.

With the combination of innovative Creaform hardware and advanced software, we are equipped to deliver comprehensive and reliable 3D laser scanning services for a wide range of applications.

Applications

ADV has routinely implemented 3D laser scanning capabilities in numerous failure analyses, engineering critical assessments (ECA) for dents and metal loss features, and the inspection of features in ILI tool calibration spools among other novel applications for integrity management. Some examples include characterizing dimensions of wrinkles in pipelines for fatigue analysis, converting scanned dents into finite element models to determine stress concentration factors (SCFs), determining corrosion growth based on current scan and previous ILI data, capturing cross-section contours through components for wall thickness measurements, and much more.

ADV is continuing to explore laser scanning capabilities in challenging situations such as wrinkles on pipes, interacting features (metal loss with surface deformation, etc.), ovality, local bulging, inner surface imperfections, etc. for a more turnkey approach to integrity management where inspection, analysis, and repairs can be handled in single, seamless projects.

Contact

Learn more about ADV's Advanced Engineering and Analysis services

For more information on how ADV can implement 3D laser scanning into your analysis processes, contact Ahmed Hassanin or Atul Ganpatye.