1 min read

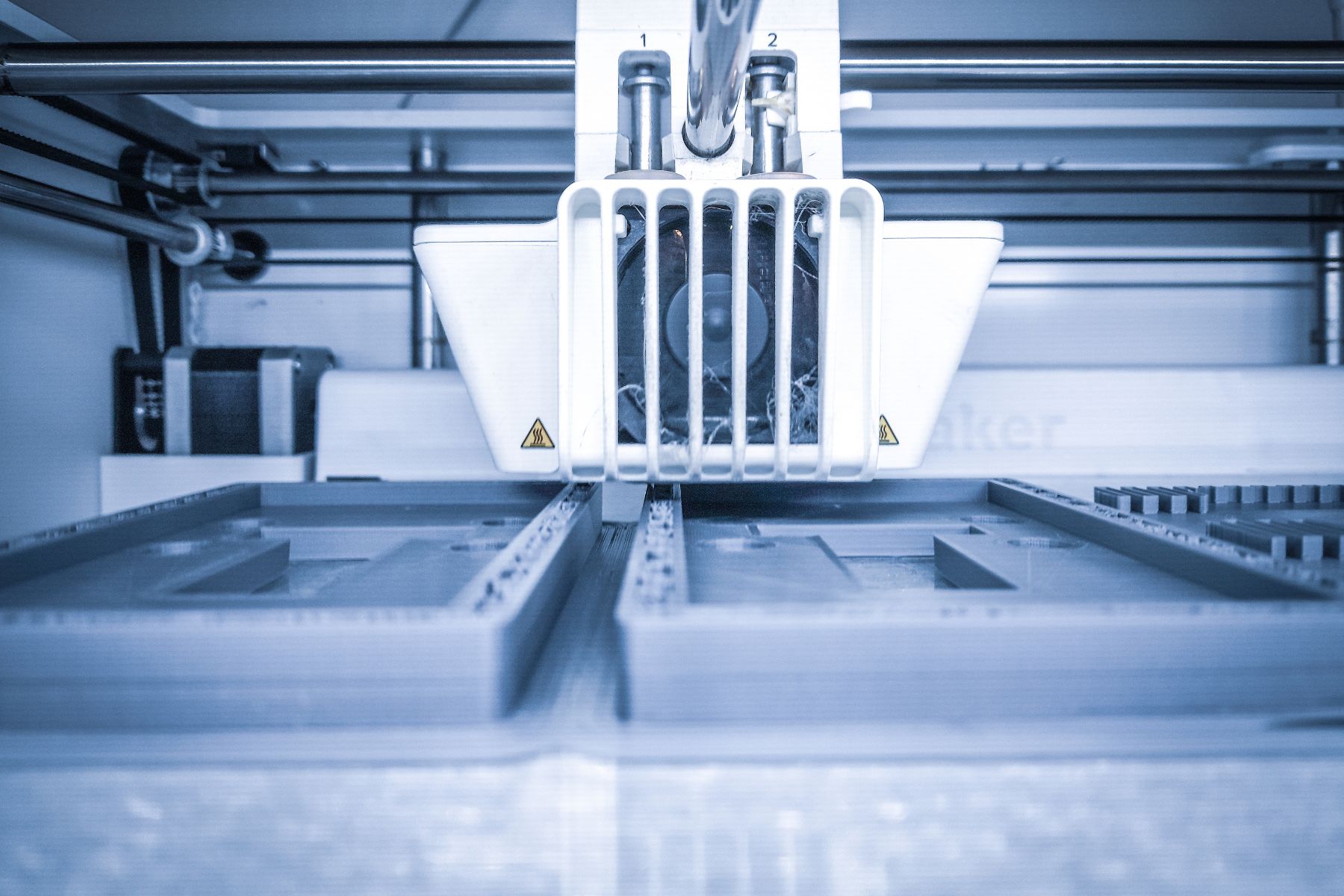

Something to Add: Validating Additive Manufacturing for Critical Applications in Oil & Gas

Atul Ganpatye, PE

8/2/23 3:38 PM

Atul Ganpatye, PE

8/2/23 3:38 PM

Additive manufacturing (AM) is set to become a credible (and disruptive!) alternative to traditional manufacturing in cases involving on-demand, customized, and highly specialized products and/or components. AM can readily and efficiently incorporate complex solutions culminating from generative design or light weighting efforts—sometimes rather difficult to achieve using traditional manufacturing methods. Cutting edge advances in the AM field are poised to bring about a paradigm shift in the conventional manufacturing and supply chain approaches in the industry.

Atul Ganpatye, Senior Associate at ADV Integrity, studies AM process and applications at ADV Integrity. He said, “AM opens a world of opportunities for the industry in terms of realizing complex designs with fast turnaround, efficient component inventory management, reduced failure rates, and specialty applications—provided that AM processes and parameters are properly understood and managed. The key to success will be in understanding when and how to use AM for your specific applications, and more importantly, when not to use AM. This understanding needs to be guided by carefully thought-out qualification programs.”

The relatively slower adoption of AM in the oil and gas industry is symptomatic of the lack of confidence in the applicability and suitability of AM materials, processes, and finished products, which primarily result from the lack of demonstrated or validated performance data. Some of ADV Integrity’s most recent initiatives are seeking to close this gap by integrating verification (analysis), inspection, and validation (testing) of additively manufacturing components for the oil and gas industry.

“With deep experience and expertise in mechanics and materials, ADV Integrity stands well-positioned to facilitate improved understanding of AM methods and products by building customized analysis, inspection, and testing programs to benefit our partners,” Mr. Ganpatye said. “We are in a unique position to bring a broad, systemic perspective to the table for AM applications, starting from feed material considerations, all the way to performance demonstration using full-scale testing. And if things have gone too far, too fast for you, and you are dealing with failure of AM components in your application, ADV Integrity can also help with failure analysis of AM parts.”

Like most disruptive innovations in human history, AM will provide incredible opportunities to be at the forefront of change. Industry players should make the most of these opportunities and create value for innovators and end users.

Originally published on June 30, 2021