3 min read

Dent Analysis and Assessment Procedure Development

Emmanuel Valencia, MS

10/19/23 8:00 AM

Emmanuel Valencia, MS

10/19/23 8:00 AM

The Pipeline Hazardous Materials Safety Agency (PHMSA) recently added new regulations requiring in-depth analysis of dents and other mechanical damage and their potential impacts on pipeline integrity. 49 CFR 192.712(c) became effective on August 24, 2022, and required Operators to develop procedures to evaluate dents and other mechanical damage using engineering critical assessment.

Engineering critical assessment (EcA)

ADV Integrity, Inc. (ADV) has developed the Pipeline Defect Modeling and Analysis Calculator (PDMAC), allowing a fast, consistent, and rigorous ECA of pipeline dents. Using the PDMAC, ADV can assist Operators in evaluating the severity of dents and other mechanical damage using ILI data or in-the-ditch measurements along with pressure history data.

The PDMAC includes the calculation of dent strain in accordance with ASME B31.8 and remaining life analysis (RLA) or fatigue analysis in accordance with API RP 1183. PDMAC also incorporates an efficient ILI data smoothing/filtering algorithm that minimizes the systemic and high-frequency noise in the ILI data, resulting in a more robust assessment process. The purpose of a dent strain assessment is to determine the maximum deformation strain associated with a dent, which serves as a proxy for the likelihood of the presence of cracks during dent formation (i.e., at the time of indentation). If the calculated strains exceed the allowable strains, the existence of formation cracks is assumed, and the dent is classified as "injurious."

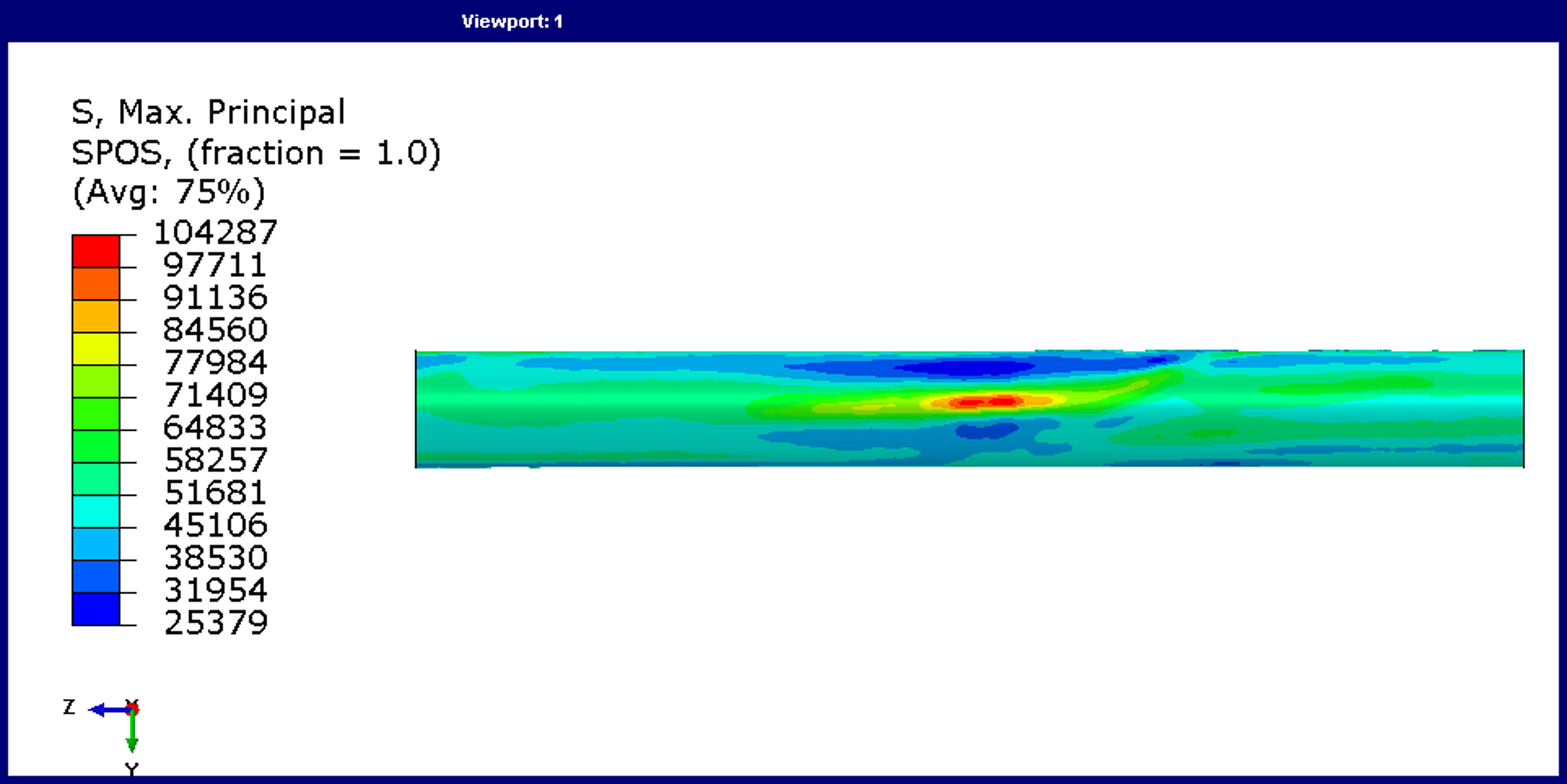

An RLA aims to determine a dent's estimated fatigue life under cyclic loading conditions. This assessment uses stress concentration factors (measure of stress risers) associated with a dent shape in conjunction with operational stress range due to pressure fluctuations. The stress concentration factors are calculated using finite element analysis of the dent, and the operational stress range is incorporated through rainflow analysis on the pressure history - these two factors are then used with an appropriate fatigue curve to estimate fatigue life.

When dealing with many dents in a dent tally, ADV can guide a multi-stage process in which the dents are progressively "filtered" for more refined assessment. This process is akin to Level 1, Level 2, and Level 3 assessments in the fitness for service (FFS) universe. Levels 1 and 2 typically employ relatively conservative, spreadsheet-based calculations that can be scaled to screen many dents, whereas Level 3 assessment involves a detailed finite element modeling and analysis approach for a select set of severe dents (that do not pass the screening criteria for preceding levels). This thorough assessment allows the Operator to focus resources on those dents that impact pipeline integrity.

Dent and Other Mechanical Damage Response Procedural Development

In addition to assessment support, ADV can assist Operators with developing their dent and other mechanical damage response procedures. These procedures are based on §192.712(c), §192.714, §192.933, §195.452, API 579, ASME B31.8, ASME B31.8S, and API 1183, depending on the product transported and the Operator's specific requirements. Where the regulations allow flexibility, the procedures can be tailored to each Operators' integrity management philosophies. While the new codes are specific to natural gas pipelines, similar procedures can also be developed for hazardous liquid and highly volatile liquid (HVL) pipeline applications. Typically, procedures include a response matrix establishing timeframes for dent and other mechanical damage evaluations. These response times are based on 49 CFR 192 and 195 requirements and industry standards for areas not covered by regulatory guidance.

In a rapidly evolving regulatory landscape, ADV Integrity is a trusted partner for Pipeline Operators seeking to navigate the complex realm of dent assessment procedure development. Our commitment to providing fast, consistent, and rigorous engineering critical assessments enables Operators to ensure the integrity and safety of pipeline operations. Our capacity to tailor response procedures to individual operator requirements highlights our adaptability in developing unique, Operator-specific solutions.

Contact

Learn more about ADV's Advanced Engineering and Analysis services

For more information on how ADV can help your company navigate dent assessment procedure development, contact Emmanuel Valencia, Cary Windler, or Atul Ganpatye.

Cary Windler, PE, M.Ed

Staff Consultant

Cary has over 17 years of experience in the oil and gas industry, specializing in pipeline integrity and integrity management programs. In his current role at ADV Integrity, he assists clients with testing protocol development to ensure safe operations of their pipelines.