3 min read

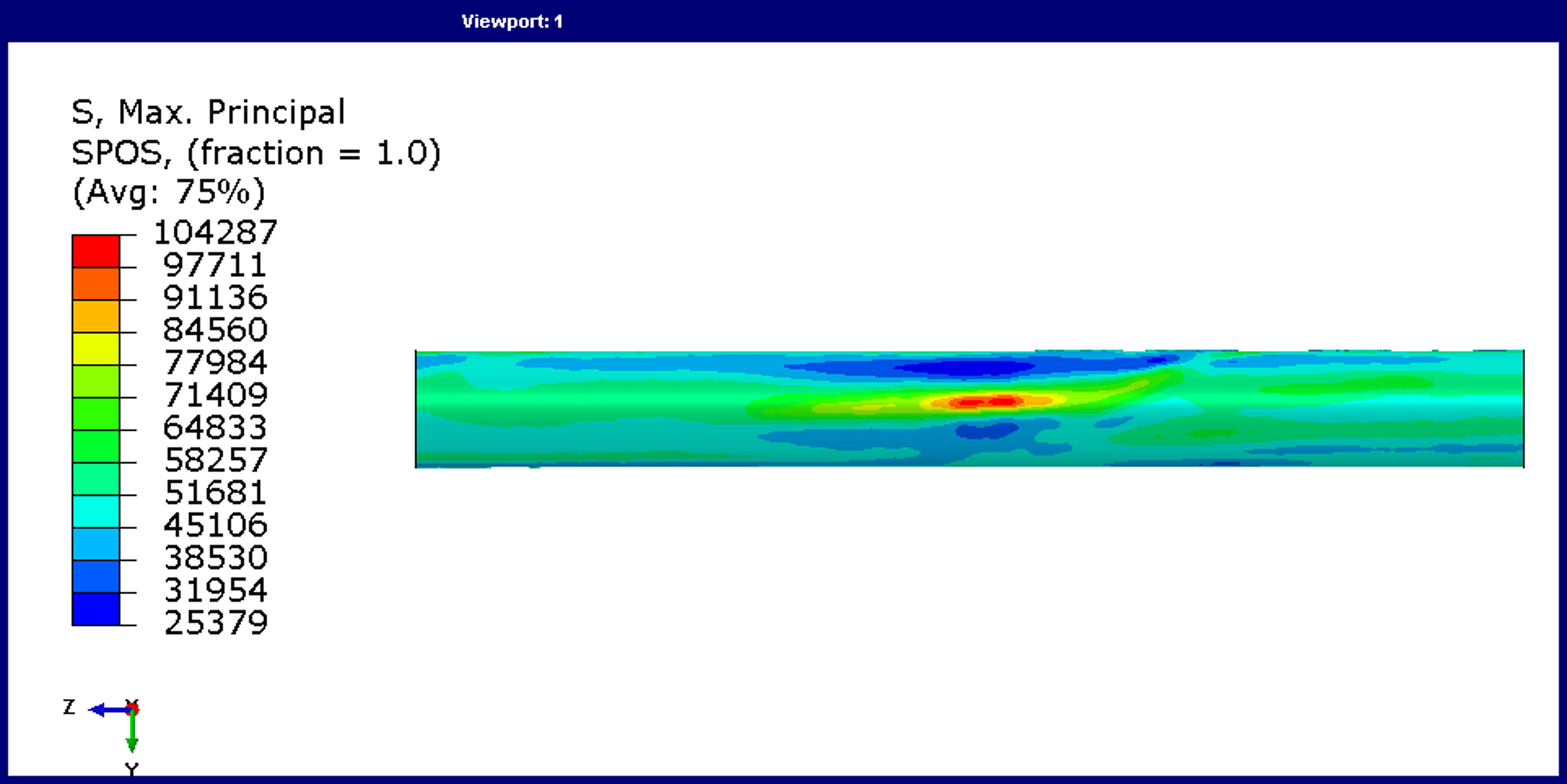

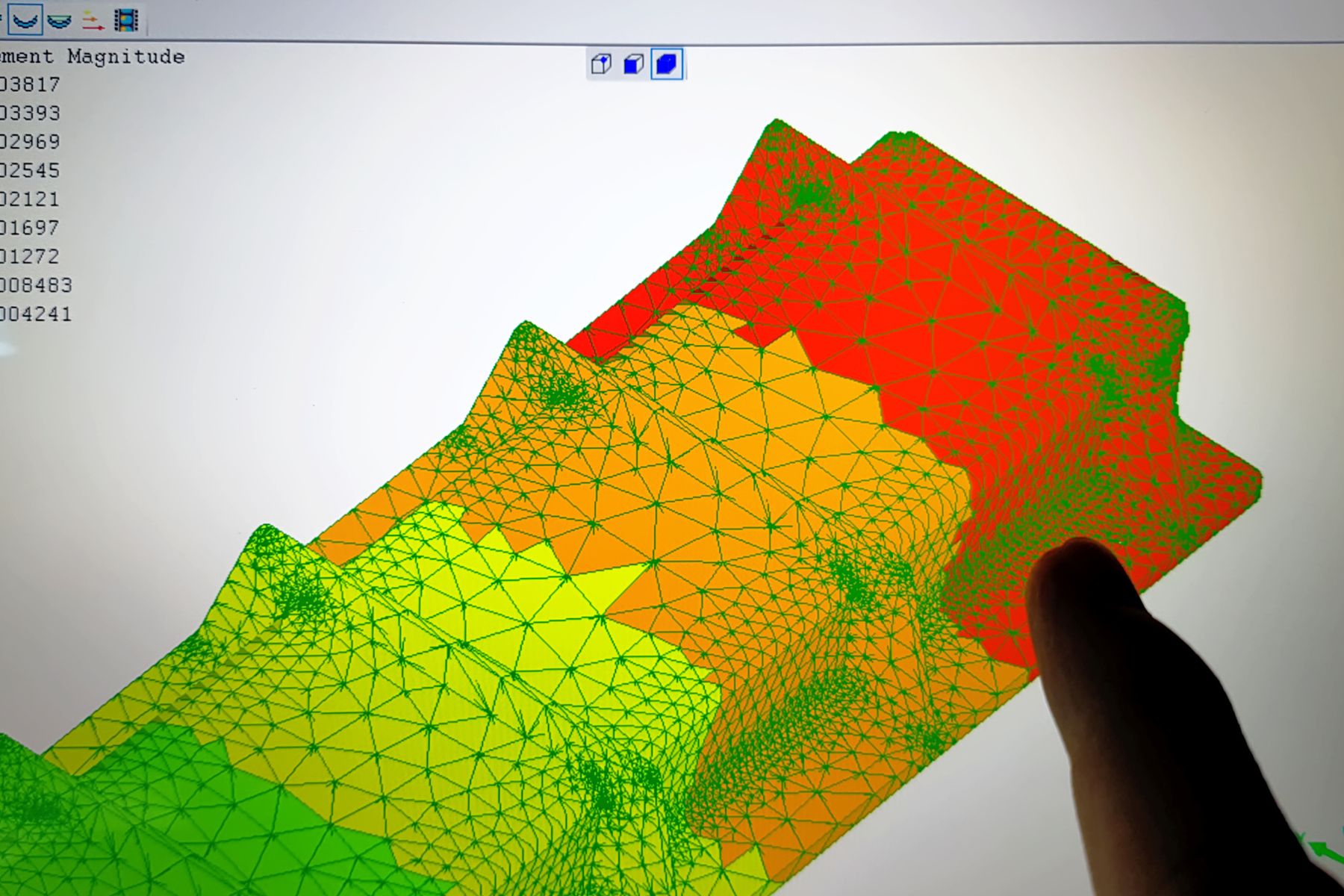

Dent Analysis and Assessment Procedure Development

The Pipeline Hazardous Materials Safety Agency (PHMSA) recently added new regulations requiring in-depth analysis of dents and other mechanical damage and their potential impacts on pipeline integrity. 49 CFR 192.712(c) became effective on August...

Read More